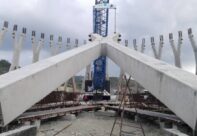

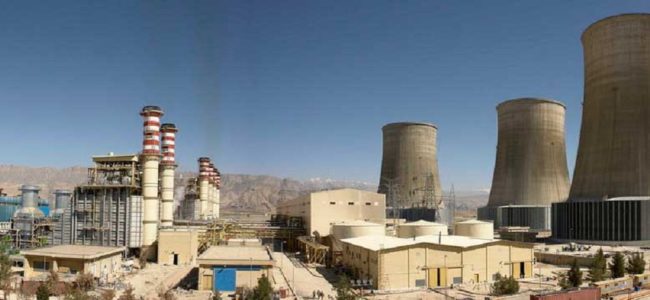

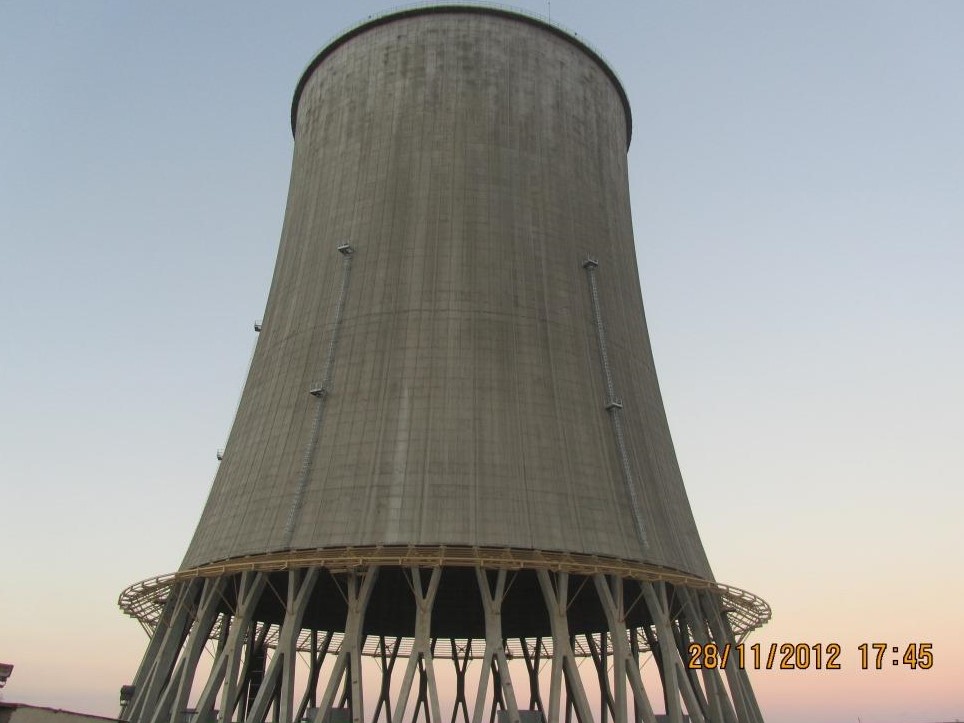

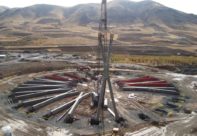

Construction operations of concrete cooling tower of Latakia Combined Cycle Power Plant

Construction of 540 MW combined cycle power plant of Latakia. Due to the increase in electricity demand in Syria, the need to re-implement the industrial, agricultural, service and tourism sectors were put in the agenda. Performing the remaining construction operations of concrete cooling power of Latakia combined cycle power plant in Al-Rastan, next to Dam 16 Tishreen was put in the agenda of this project to provide the conditions for absorbing heat produced by the electricity generation operations.

Status of Project: In ProgressProject Highlights

Role of Parhoon Tarh Contractor of Construction Operations

ClientConstruction and development of MAPNA Combined Cycle Power Plant (Tosse 2)

Location Syria- Latakia

Project Cost 6 million Euro

Project Duration 15 months

Project images

Project Volumes

Concrete work: 13,000 m3

Excavation: 13,000 m3

Traditional Formwork: 4.600 m2<

Framing X-LEG column’s formwork: 5.200 m2

Shell Climbing frame: 46,000 m2

Upper ring formwork: 400 m2

Reinforcement: 4,000 tons

Steel structures: 320 tons

Embankment: 7,500 m3

Number of X-LEG column: 32

Project Specification

Number of cooling towers: One unit

Height of the towers from foundation: 134m

Maximum diameter: 83m

Thickness: 18 to 125cm

Project Goals

- The cooling system of combined cycle power plant