Financing and Execution the Project aimed at Organizing Minab Dam Downstream River

Minab downstream River is one of the important rivers in Hormozgan Province, that floats in Minab plain, in approximately 120 kilometer distance from east Bandar Abbas. Minab Dam has been built to harness the flood and provide sustained drinking and agricultural water in Dasht Minab region, as well as for supplying drinking water in Bandar Abbas City. The goal of this project is to organize, dredge and control Minab river flood.

Status of Project: In ProgressProject Highlights

Role of Parhoon Tarh: Contractor of Construction Operations, and Site Building

Project investor: Tana Energy and Parhoon Tarh Joint Venture

Client: Hormozgan Regional Water Company

Consultant Engineer: Sabzab Arvand Consultant Engineers Company

Location: Hormozgan Province- Minab City

Project Cost:790 billion IRR

Project Duration: 12 months

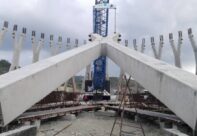

Project images

Project Volumes

Concrete work: 46,000 m3

Excavation: 902,000 m3

Embankment: 803,000 m3

Geotextile: 156,000 m3

Stone structures: 183,000 m3

Project Specification

Length of the right dike of the river: 7,880 m

Length of the left dike of the river: 6,790 m

Height of the dike: 3.5m , 4.5m and 5.5 m

Concrete pipes: 700 to 1000 mm diameter

Type of operations: River organizing

Project Goals

- Building soil dike in the planned dimensions by using geotextile filter materials, construction of gable surface and pebbles in cement mortar for non-urban areas in the right and left banks of the river

- Dikes heels protection operations including digging canals and pebble mortar filling in designed dimensions in 2.5m length

- The drilling, dredging operations, collecting and discharging surface waters in the dikes’ back, and construction of dike underpass structures to direct the dredged water into the river

- Collecting river materials for dike construction, and clearing the path of the last area (the lowest stream in the area).